Membrane Bioreactors Clarified: Efficient Solutions for Clean Water

Membrane bioreactors (MBRs) have actually become an innovative option for addressing journalism obstacles of wastewater therapy. By incorporating biological processes with innovative membrane filtering, MBRs not only improve the high quality of treated water yet additionally reduce the spatial requirements of treatment centers. As environmental concerns escalate, the duty of MBR modern technology in advertising sustainable water management comes to be significantly substantial. Nevertheless, the complexities of their procedure, benefits, and prospective applications warrant a closer evaluation to fully recognize their effect on the future of water therapy.

What Are Membrane Bioreactors?

Membrane bioreactors (MBRs) are advanced wastewater therapy systems that integrate organic deterioration processes with membrane filtering innovation. This integration enables the reliable removal of contaminants from water, making MBRs a favored option in different applications, including metropolitan wastewater treatment and industrial effluent monitoring.

Among the vital benefits of MBRs is their capability to generate premium effluent, often appropriate for reuse in irrigation or industrial processes. Furthermore, MBRs need a smaller sized footprint contrasted to standard therapy systems, making them perfect for city settings where space may be limited.

In addition, MBRs can effectively handle varying influent tons and are much less vulnerable to the impacts of hazardous shocks. These characteristics add to their growing popularity as a lasting option for resolving the raising demand for clean water while reducing environmental influences.

Exactly How Membrane Layer Bioreactors Job

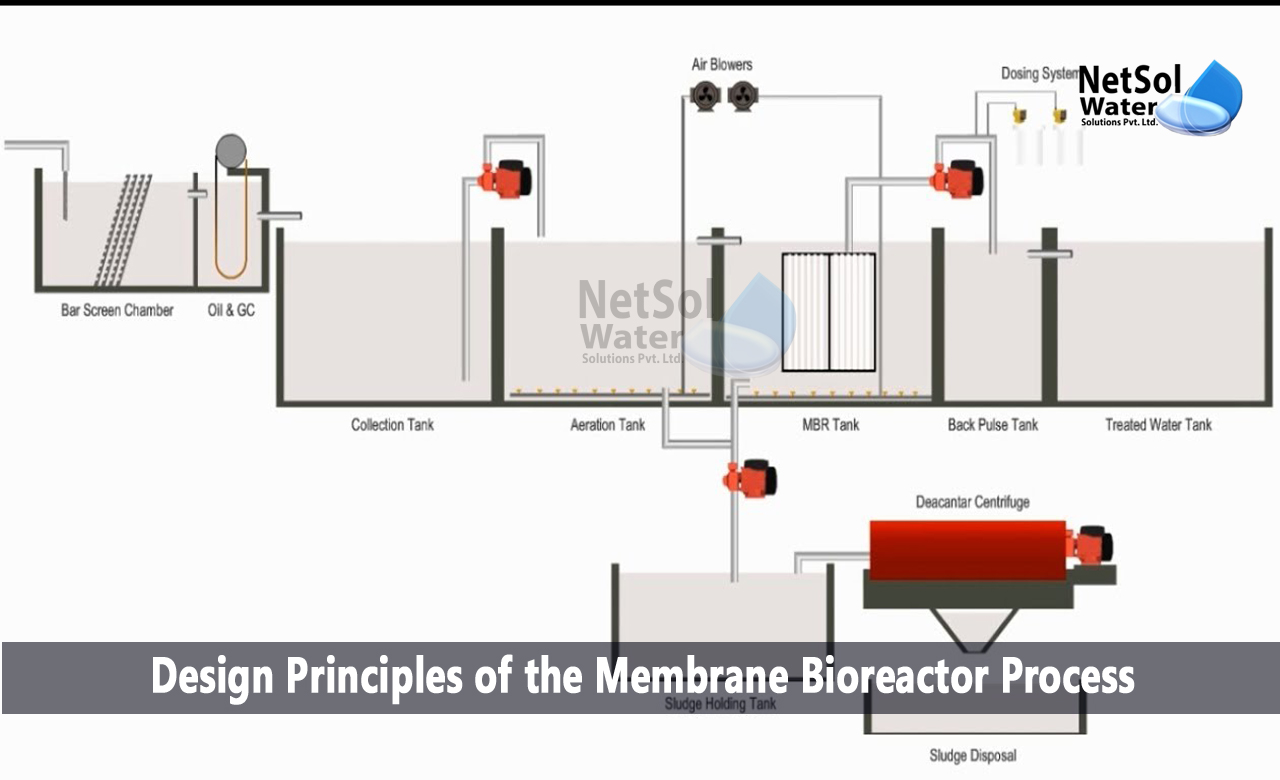

While the procedure of membrane layer bioreactors (MBRs) might seem complicated, it basically focuses on the synergy between organic procedures and membrane layer filtering. MBRs integrate a biological therapy procedure, commonly activated sludge, with a membrane layer splitting up unit to deal with wastewater successfully.

In an MBR system, wastewater is initial introduced right into a bioreactor where microorganisms weaken raw material and various other impurities. The biological task lowers the concentration of pollutants while advertising the growth of biomass. Following this biological therapy, the mixed alcohol goes through membrane purification, which can be microfiltration or ultrafiltration, depending on the wanted effluent high quality.

The membranes work as a physical obstacle, enabling water and small solutes to pass while maintaining suspended solids and bigger molecules. This makes it possible for the system to maintain a high concentration of biomass within the reactor, improving the therapy efficiency.

Moreover, the continual separation of cured water from the biomass promotes a small design and lessens the impact of the treatment facility. On the whole, the combination of biological destruction and membrane filtering in MBRs leads to reputable and effective wastewater therapy, guaranteeing high-quality effluent ideal for numerous applications.

Advantages of MBR Modern Technology

Among the key advantages of membrane bioreactor (MBR) modern technology is its capacity to produce premium effluent with a considerably lowered impact compared to conventional wastewater treatment techniques. MBR systems properly incorporate biological treatment and membrane filtering, resulting in premium elimination of pollutants, including put on hold solids, virus, and raw material. This ability leads to effluent that usually fulfills or surpasses stringent regulative criteria for reuse and discharge.

Additionally, MBR modern technology permits greater biomass concentrations, which enhances the therapy efficiency and minimizes the required activator quantity. This portable design is especially beneficial in find here metropolitan locations where space is limited. The functional adaptability of MBR systems also indicates they can adjust to varying influent top qualities and flow rates, making them ideal for a wide variety of applications.

In addition, the reduced sludge manufacturing connected with MBR processes adds to decrease functional and maintenance costs. The membranes offer as a physical barrier, minimizing the risk of blocking and making it possible for longer functional durations in between cleaning. Overall, the advantages of MBR innovation make it an attractive option for lasting wastewater therapy, resolving both ecological problems and the need for efficient resource management.

Applications of Membrane Layer Bioreactors

With their flexibility and effectiveness, membrane bioreactors (MBRs) find applications across numerous sectors, consisting of local wastewater treatment, commercial processes, and even water reclamation. In municipal settings, MBRs provide a portable remedy for treating wastewater, effectively removing contaminants while at the same time producing high-grade effluent that fulfills rigid regulative standards. This makes them particularly suitable for locations with restricted area.

In commercial applications, MBR modern technology is made use of for treating process water, pop over to this site especially in markets such as food and beverage, drugs, and petrochemicals. These markets profit from MBRs' capacity to take care of high organic loads and their efficiency in recouping useful resources from wastewater, such as nutrients and water.

In addition, MBRs play a critical role in water reclamation campaigns, allowing the reuse of treated wastewater for irrigation, industrial procedures, or even as safe and clean water after more therapy (Membrane Bioreactor). Their effectiveness in removing contaminants and pathogens makes them a reliable selection for guaranteeing water high quality in different reuse applications

Future of Water Therapy Solutions

The future of water treatment options is positioned for transformative improvements driven by technological advancement and increasing environmental awareness. As international water scarcity ends up being a pushing issue, brand-new methodologies, including membrane layer bioreactor (MBR) systems, are readied to play a crucial role Home Page in improving the performance and sustainability of water treatment procedures.

Emerging innovations such as expert system and equipment discovering are anticipated to optimize treatment operations, permitting for real-time monitoring and predictive upkeep. This will certainly improve the general dependability and performance of water therapy facilities. Moreover, improvements in membrane layer materials, such as graphene and nanofiltration, guarantee to raise permeation prices and decrease fouling, leading to lower energy usage and operational prices.

Additionally, the assimilation of renewable power resources right into water therapy plants will certainly add to greener methods. The round economic climate design will certainly likewise gain grip, urging the recovery of beneficial sources from wastewater, such as nutrients and energy.

Conclusion

Membrane layer bioreactors (MBRs) have arised as an advanced remedy for attending to the pressing challenges of wastewater treatment. By incorporating biological procedures with innovative membrane purification, MBRs not only improve the quality of cured water however additionally reduce the spatial demands of treatment centers.One of the essential benefits of membrane layer bioreactor (MBR) innovation is its capacity to create high-quality effluent with a substantially reduced footprint compared to standard wastewater treatment methods.With their adaptability and efficiency, membrane layer bioreactors (MBRs) locate applications throughout different markets, including local wastewater therapy, commercial processes, and also water reclamation.In final thought, membrane layer bioreactors stand for a significant innovation in wastewater treatment innovation, incorporating organic procedures with efficient membrane layer purification to generate top quality effluent.

Comments on “Membrane Bioreactor as a Sustainable Solution for High-Volume Wastewater Treatment”